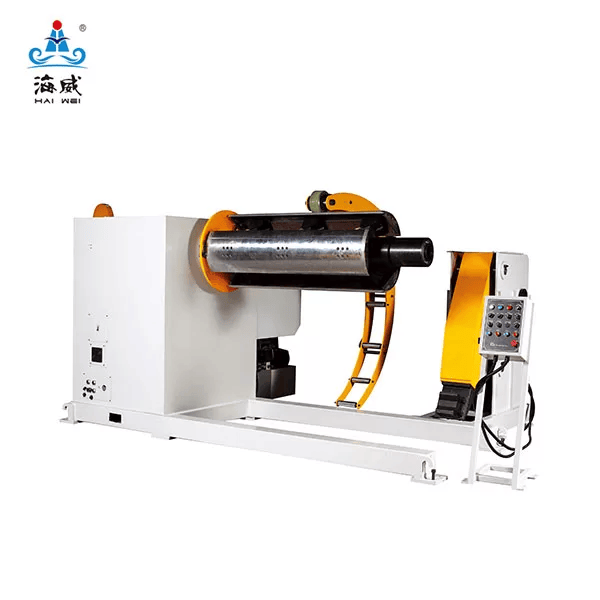

Decoilers are one of the important equipment in the modern manufacturing industry and play a key role in handling different types of coil materials. Whether metal, plastic, or composite materials, decoilers offer the versatility to help manufacturers process various types of coils efficiently and accurately.

The basic function of decoilers is to support and unfold coils such as metal sheets, wires, or strips with unparalleled precision for the subsequent manufacturing process. This process is a critical aspect of the manufacturing process as it ensures a steady and precisely controlled feed of material, resulting in a smooth and efficient manufacturing operation.

In the following sections of this article, we’ll look at the versatility of decoilers in handling different types of coils, including metals, plastics, and composites. Moreover, we will explore the remarkable innovations in coil handling technology that have redefined the landscape of modern manufacturing.

Handling Metal Coils

In the field of decoilers, the handling of metal coils is the most common and important task in modern manufacturing. Metal coils, especially those made of steel, aluminum and copper, are a common material processed by metal decoiler machines in various industries. These metals come in different thicknesses and sizes, and decoilers are specifically designed to handle these coils with precision and expertise.

The uncoiling process of metal coils involves the use of a tensioning mechanism, which plays a key role in controlling the tension on the coil during the uncoiling process. The purpose of this tension control is to prevent breakage or damage that could affect the quality of the material. Decoilers excel at maintaining the integrity of the material by providing consistent and precise tension control throughout the entire decoiling process.

Additionally, decoiler speed is a key variable in processing metal coils, and decoilers can flexibly adjust speed to the specific size and thickness of the coil. This adaptability ensures that the unwinding process is not only efficient but can be customized to the unique characteristics of each coil. This level of control ensures that materials remain intact and ready for further processing without the risk of snags, blockages or other disruptions to operations.

The handling of metal coils is a fundamental task in modern manufacturing, and decoilers play a central role in ensuring the efficiency and quality of the process. Their ability to control tension, adjust unwind speed and adapt to a variety of materials and roll sizes ensures manufacturers can meet the diverse needs of their customers.

Handling Plastics and Composites

In recent years, there have been significant changes in the types of materials used in manufacturing. While metals remain popular, other materials such as plastics and composites are gaining attention because of their unique properties and advantages. Plastic is known for its lightweight and versatility, making it suitable for a wide range of applications. Composite materials, on the other hand, are engineered materials that combine the strength of different components, offering a high strength-to-weight ratio and corrosion resistance.

These changes in material preferences create new challenges for manufacturers, requiring specialized handling to prevent damage and maintain quality. As a result, uncoilers have undergone significant adjustments to meet these changing needs.

Decoilers are specifically designed to handle a wider range of coil sizes and weights typically associated with plastics and composites. Haiwei’s decoilers for sale are known for their flexibility, they can easily switch between different coil sizes and materials to meet the changing needs of customers.

Innovations in Coil Handling Technology

To handle many types of coil materials, decoiler machines need constant innovation in design and engineering. These new ideas improve many parts of the process for handling coils by using advanced technology. Modern decoilers can handle different coil types well due to these key innovations. Let’s examine them closely.

Adjustable Spindle

Decoilers nowadays have mandrels that can change to fit various coil sizes. You can adjust the mandrels to fit different coil sizes and positions, so they always hold securely. Manufacturers can easily switch between coil sizes, saving time and improving efficiency.

Quick Change System

Efficiency is critical in manufacturing. The quick-change system revolutionizes coil handling by enabling quick coil changes. Uncoiler machines use hydraulic or pneumatic clamps to reduce downtime between production runs. The controls and interface are user-friendly, which makes coil changes easy for the operator.

Variable Speed Control

Different materials require different processing speeds. Manufacturers can adjust the speed of uncoiling for different materials using variable speed controls. To avoid damage, thin materials should unwind at slower speeds. Thicker materials can unwind faster for productivity.

Tension Control System

It is important to control tension precisely so that materials do not wrinkle or stretch. Tension control systems have improved using load cells and sensors for real-time feedback. We adjust the tension in real-time to keep it perfect for the material we’re working with.

Automatic Edge Control

In coil processing, edge control is crucial. Modern sheet metal decoilers use advanced edge control technology to monitor the edge of the coil and make real-time adjustments. To prevent defects, it’s important to keep the material aligned and straight in the final product.

Security Innovation

In any manufacturing environment, safety is critical. Decoilers have safety features like emergency stop buttons, light curtains, and interlocks. These protect operators and prevent accidents. Predictive maintenance technology is used to find and fix problems before they cause breakdowns or safety issues.

Conclusion

The versatility of decoilers in handling a variety of coil materials demonstrates their integral role in modern manufacturing. They can adapt to metals, plastics, and composites. Decoilers are also good at maintaining material integrity, controlling unwind speed, and providing precise tension control.

Innovations such as adjustable spindles, quick-change systems, variable speed controls, precision tension control systems, automatic edge control, and advanced safety features have revolutionized decoiler technology. These improvements make it easier to handle coils, reduce downtime, and increase efficiency. This ensures a high-quality product that meets modern manufacturing standards.

In an evolving manufacturing environment, decoilers remain critical, enabling streamlined, efficient and safe processes to meet changing industry needs.

Share This Post: